Información Básica.

No. de Modelo.

HMC Q

Control Numérico

CNC / MNC

Precisión Procesamiento

0,03 \ sim 0,04 (mm)

Condición

Nueva

sistema de control cnc

GSK, Fanuc, Siemens

velocidad de avance (mm/min)

1 - 36000 mm/Min

función

Milling, Drilling,Tapping

Paquete de Transporte

Wooden Case

Especificación

3250*2650*2650mm

Marca Comercial

RICH

Origen

Dalian, China

Capacidad de Producción

100 Set Per Week

Descripción de Producto

RICH Save Energy CNC Metal Milling Machine CNC Lathe Horizontal Machining Center

Product Description

Product Description

Inverted T-shaped integrally cast bed

Y-axis motor base and column are casted together

Thermally symmetrical spindle

Product Paramenters

Product Paramenters

Product Description

Product Description Horizontal Machining Center(Q Series)

HMC-Q series horizontal machining center is a new generation of highperformance and compact machine. It has excellent quality, high reliability and efficiency. It is widely used in auto parts, pump,valves and other industries. It can meet the processing requirements of single or small batch products with high efficiency

Product Features

1. High stability structureProduct Features

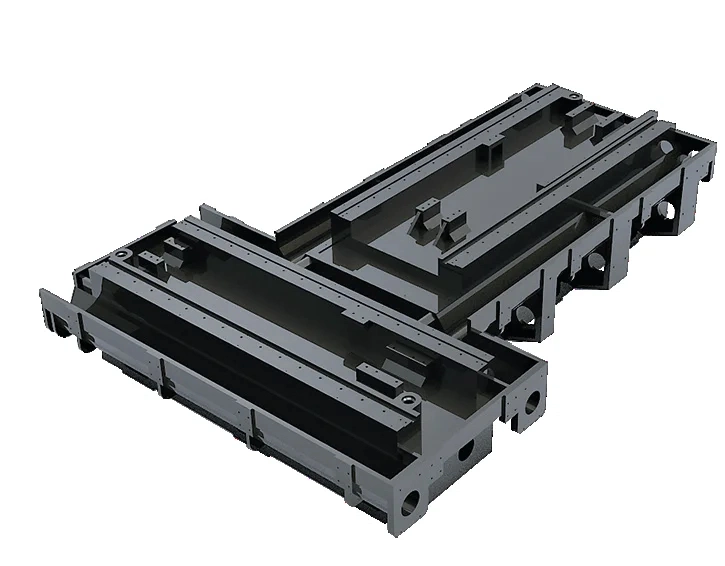

Inverted T-shaped integrally cast bed

Y-axis motor base and column are casted together

Thermally symmetrical spindle

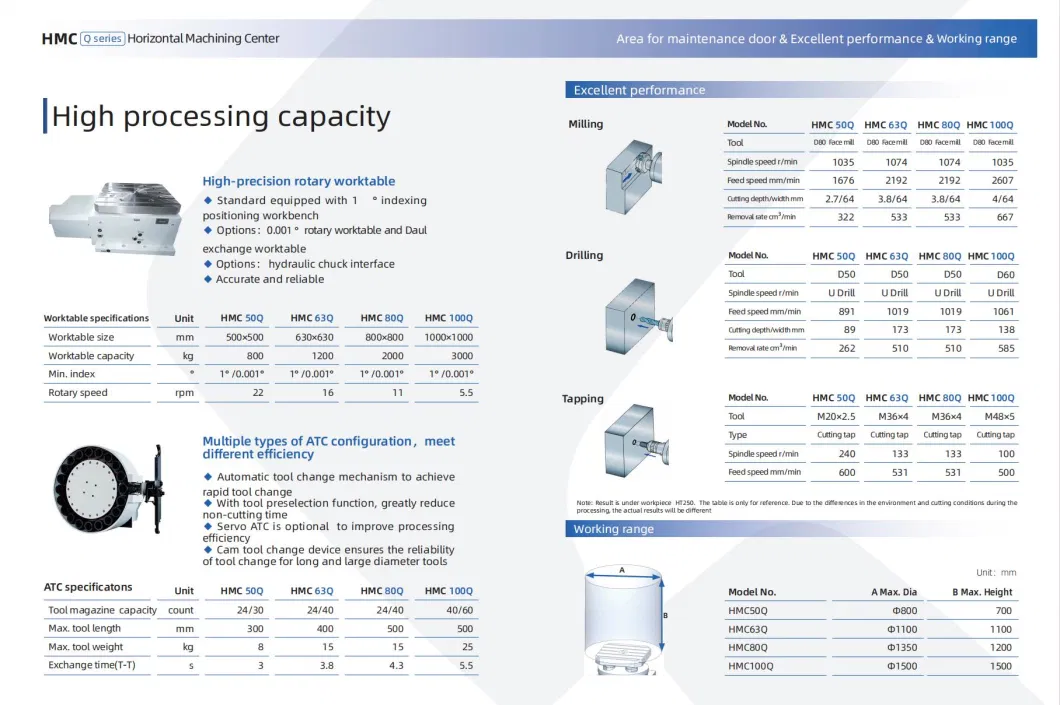

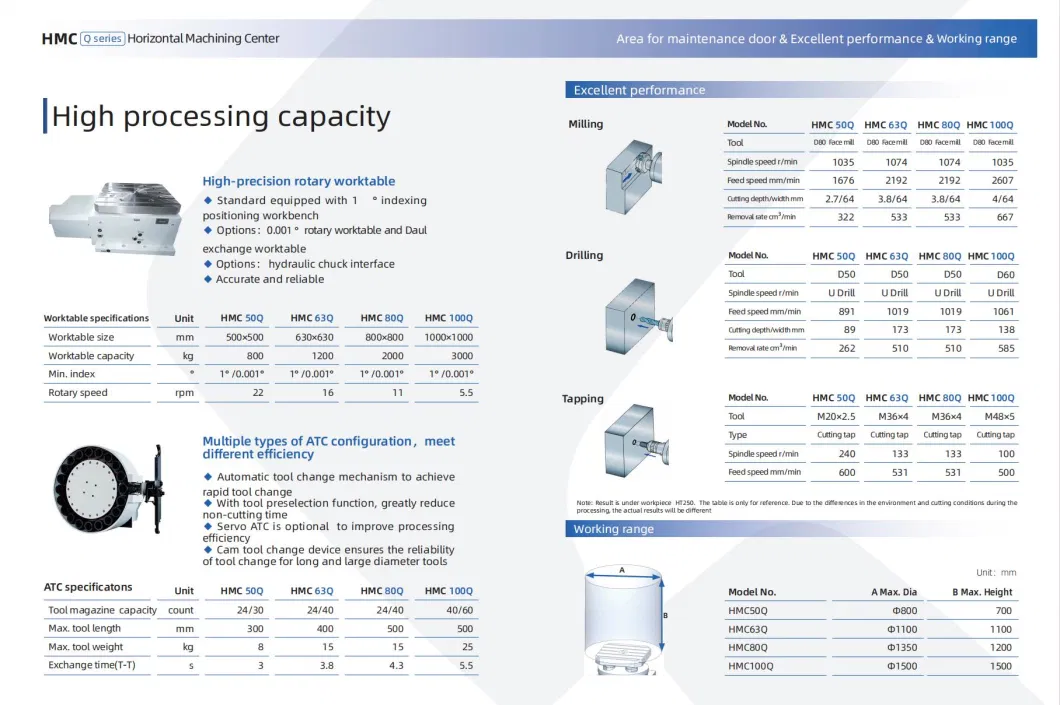

2. High processing capability

Gearshift headstock

Multi-spindle selection to meet different working conditionsMultiple types of tool magazine configuration,meet different efficiiency

Gearshift headstock

Multi-spindle selection to meet different working conditionsMultiple types of tool magazine configuration,meet different efficiiency

3. High intelligent function

Intelligent check and maintenance plan

Automatic data backup

Spindle intelligent load control

Product Details

Intelligent check and maintenance plan

Automatic data backup

Spindle intelligent load control

Product Details

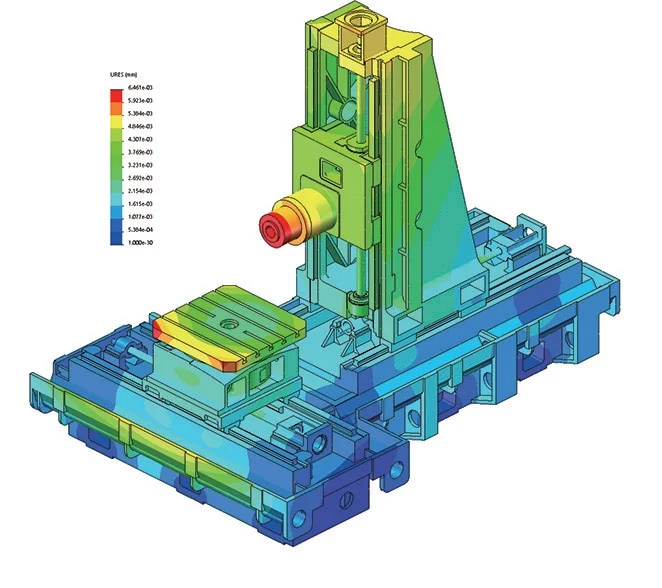

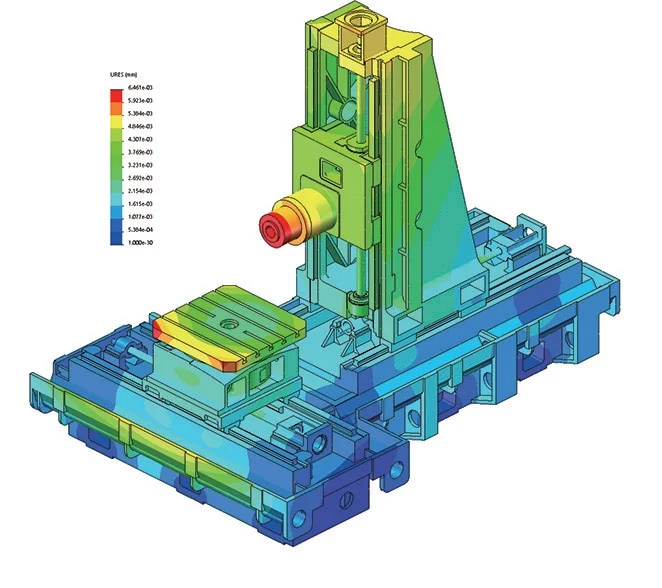

Finite element and topology optimization structure

The machine tool is designed with finite element analysis and well stiffened, the overall structure and large part are optimized to improve the rigidity and stability of the whole machine.

High strength integrally cast bed

Inverted T-shaped integrated bed, large span, low center of gravity, well stiffened, strengthened anti-deformation,using 4 groups of twisted cage for chip removal ensure removal efficiency

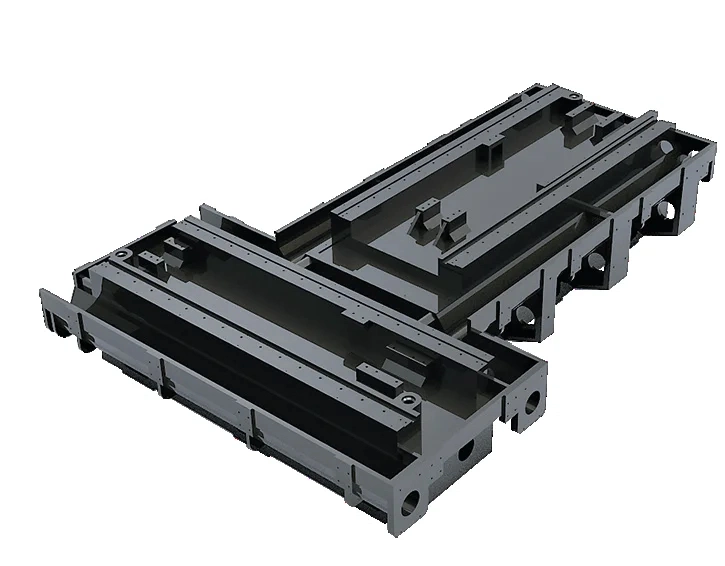

Y-axis motor base and column are casted together

Double-wall structure is adopted by the columns of this series, Y-axis motor base and column are

casted together to improve the accuracy and stability of machine tool

casted together to improve the accuracy and stability of machine tool

Thermally symmetrical spindle

Thermal symmetry spindle improve the controllability of thermal deformation; Excellent thermal stability.

Precision ball screw

All three axes are equipped with

precision ball screw, pre-stretching process is adopted to effectively reduce the influence of the screw heating during working, improve the accuracy of the machine tool, strengthened anti-deformation ability and accuracy retention.

precision ball screw, pre-stretching process is adopted to effectively reduce the influence of the screw heating during working, improve the accuracy of the machine tool, strengthened anti-deformation ability and accuracy retention.

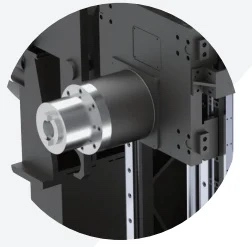

Mechanical spindle

Two gear shift speed change is adopted to

achieve from high-speed machining to heavy cutting

Large-span bearing arrangement, high rigidity

achieve from high-speed machining to heavy cutting

Large-span bearing arrangement, high rigidity

| Item | Unit | HMC 50Q | HMC 63Q | HMC 80Q | HMC 100Q |

| Work table | |||||

| Worktable size | mm | 500*500 | 630*630 | 800*800 | 1000*1000 |

| Worktable capacity | kg | 800 | 1200 | 2000 | 3000 |

| Number of worktable | pcs | 1(2) | 1(2) | 1(2) | 1(2) |

| Working range | |||||

| X axis travel | mm | 750 | 1000 | 1350 | 1800 |

| Y axis travel | mm | 600 | 900 | 1100 | 1500 |

| Z axis travel | mm | 600 | 900 | 1100 | 1350 |

| B-axis indexing | 1° ×360 | 1° ×360 | 1° ×360 | 1° ×360 | |

| Max. rotation diameter of workpiece | mm | Φ800 | Φ1100 | Φ1350 | Φ1500 |

| Distance from spindle nose to worktable center | mm | 750Max | 1050Max | 1300Max | 1650Max |

| 150Min | 150Min | 200Min | 300Min | ||

| Distance between s p i n d l e n o s e t o worktable surface | mm | 650 Max | 900 Max | 1100 Max | 1600 Max |

| 50Min | 0Min | 0Min | 0Min | ||

| Spindle | |||||

| Spindle taper (7: 24) | BT40 | BT50 | BT50 | BT50 | |

| Maximum speed | rpm | 8000 | 6000 | 6000 | 4500 |

| Spindle motor power (continuous/S2) | kw | 7.5/11 | 15/18.5 | 15/18.5 | 18.5/22 |

| Maximum output torque(continuous/S2) | nm | 53/105(15min) | 433/713(15min) | 433/713(15min) | 713/871(15min) |

| Tool magazine | |||||

| Tool magazine capacity | PCS | 24 | 24 | 24 | 24 |

| Max. tool length | Mm | 300 | 400 | 500 | 500 |

| Max. tool weight | kg | 8 | 15 | 15 | 25 |

| Max. tool diameter full/empty | mm | Φ78/Φ120 | Φ110/Φ220 | Φ110/Φ220 | Φ125/Φ250 |

| Tool change time(T-T) | s | 3 | 3.8 | 4.3 | 5.5 |

| Feed | |||||

| Maximum cutting feed speed(X/Y/Z) | Mm/min | 1-36000 | 1-24000 | 1-24000 | 1-20000 |

| Rapid traverse(X/Y/Z) | M/min | 36 | 24 | 24 | 20 |

| Positioning accuracy | |||||

| X/Y/Z axis | mm | 0.01 | 0.01 | 0.01 | 0.012 |

| B axis(1° X360) | '' | 10 | 10 | 10 | 10 |

| Repetitive positioning accuracy | |||||

| X/Y/Z axis | mm | 0.006 | 0.006 | 0.008 | 0.008 |

| B axis(1° ×360) | '' | 3 | 3 | 3 | 3 |

| Overall dimension(LxWxH) | mm | 3250*2650*2650 | 3700*3000*3250 | 4300*3400*3600 | 6100*5000*4600 |

| Floor space | mm | 4000*4000 | 4500*4300 | 5100*5000 | 6800*6000 |